Prototyping Design for Home Appliance

The home appliance industry is constantly changing, and new design trends seem to emerge every few months. The pace of innovation is so fast that manufacturers need to regularly update their products to stay competitive.

From your imagination to reality

Why Prototype?

We use 3D printing or any other methods for new product design, product development, and rapid prototyping. Compared with traditional processes, prototyping through additive manufacturing can reduce material use by up to 95% while improving quality because it allows for on-demand adjustments in order to release appliances that are not only polished but fully functional too.

Best choice

We'll build your Prototype Fast!

Prototyping is a way of testing something quickly by making an object that has been designed in the computer. Prototypes are created from 3D models, and they allow you to make changes easily before going into production with real objects. With short prototype lead times, you can also test for design modification several rounds until reaching market viability

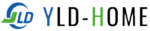

CNC Prototyping Service

This is done by using a computer numerical control (CNC) machine. The CNC prototyping procedure reduces costs, time, and the potential for errors in your product's production without compromising on quality.

Injection Molding Threads

Injection Molding Threads are designed to be used in a variety of parts for the home appliance industry. It is created by injecting molten polymer into a mold, shaping it and removing excess material from the process.

Die Casting Service

1) Die Casting (tool steel/ stainless steel);

2) Aluminum Die Casting;

3) Zinc alloy Die Casting;

4) Stainless steel and titanium;

5) Plastic Parts Extrusion.

3D Printing Service

3D printing is a process of making objects using additive manufacturing. This layer-by-layer method can produce complex geometries with internal support structures that are not possible with other fabrication methods, such as injection molding or extrusion (for metal).

Overmolding

Overmolding is a process of manufacturing an item by covering the outer surface with thermoplastic, then heating it to melt and inject the plastic into openings in the item. This creates a permanent bond between two materials too dissimilar or otherwise unsuitable to be combined on their own.

CNC Milling Machining

CNC milling machining guarantees the high accuracy tolerances of the finished product on each side as low as 0.001 inches, while simultaneous machining in multiple materials allows for functionality across almost any discipline or industry with no compromise made to quality.

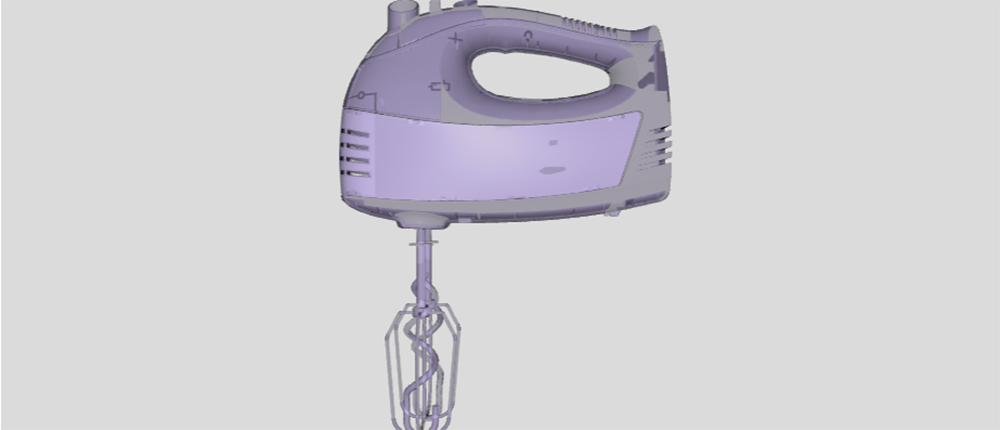

Peek Into Our Designs

development process

How to Prototype Product?

3D Drawing

Sketch your design and layout to scale on paper or in a 3D application such as Maya, Rhino, or SolidWorks.

Digital Modeling

Create a prototype of the appliance by modeling it digitally with your funds budgeted for materials and manpower (if applicable).

Manufacturing Prototype

Fabricate the prototype using any combination of casting techniques- sand molding, injection molding, etc.- when you have determined that this is feasible at an acceptable price point given all market factors associated with each technique.

successful projects & satisfied customers.

Inspired by our work?

Please fill out the form, so we can learn more about you and your needs.